What is the welding procedure for flanges?

- Necessary equipment and tools for manual welding equipment, a handle type angle grinder, an electric pneumatic hammer, a flat ruler.

- Prepare to check and debug the equipment before welding to ensure the normal operation of the equipment; Prepare 4.0J402 electrode should be dried at 300-350 C for one hour.

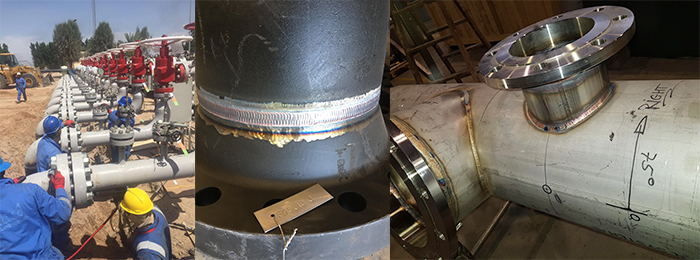

- The assembly of the welding process assembles the vertebral body and the large flange according to the drawing requirements, and then divides the big flange into eight equal parts equally. Because the flange is thicker, the groove is bigger, so the segmental symmetrical and multi-layer welding is adopted.

- The weld quality requires at least the strength of the weld metal. The surface of the weld is smooth and smooth, and has no defects such as burn through, porosity, welding leakage, slag inclusion, undercut and incomplete welding. The remaining height is less than 2mm.