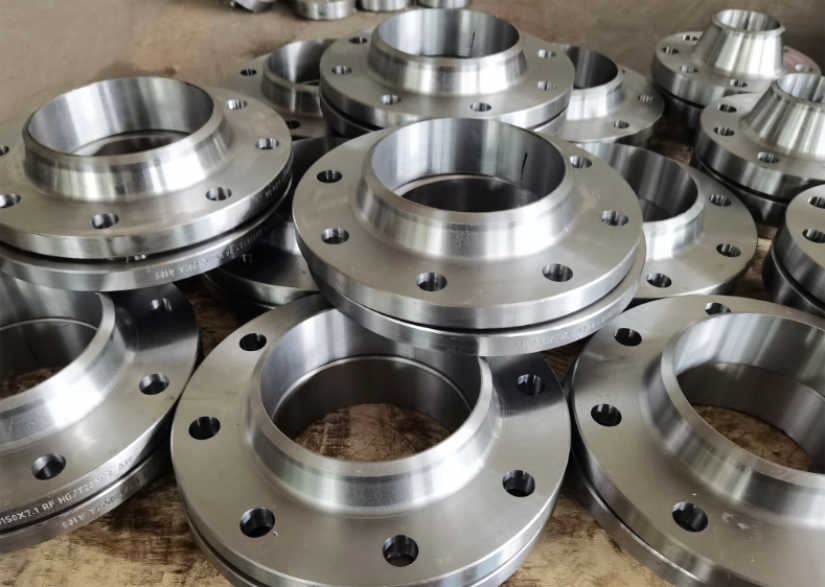

Stainless steel flange is a relatively common pipe component, with a very good application range and performance. But many people do not understand the stainless steel flange, so what is the flange? What are the advantages of flanges? How to maintain daily? I believe you are very curious about these questions, so let’s understand the flange

In the construction, it plays the role of connecting the pipe end with the valve. Both sides of the flange are connected with the end of the pipe, and the flange itself has holes. Stainless steel flanges are widely used in petroleum, chemical industry, construction, shipbuilding, paper making, medicine and other industries. The reason why stainless steel flanges are used in such a wide range is first because stainless steel flanges have excellent performance.

When welding the stainless steel flange, it is necessary to prevent the flange cover in strict accordance with the requirements to prevent damage. At the time of welding, the current is not too large, and the need to ensure rapid cooling. This is also a good way to operate.

When making stainless steel flanges, what we should use is to add appropriate stability elements to the stainless steel flanges, and such elements can be very stable to a certain extent. Many problems can also occur when welding stainless steel flanges.

For example, repeated heating will reduce corrosiveness to some extent. This situation needs attention, otherwise it will seriously affect the quality of the project.

Stainless steel flange production details

Knife friction damage fast: For the raw materials of stainless steel flange, its interior usually contains a certain amount of high melting point elements, its plasticity is large, and the temperature required for turning is relatively high, which will directly cause faster damage to the processing tool

Then it involves the need to convert or replace the damaged tool. In this way, it will not only increase the input cost of the tool but also affect the operation of the entire production line and reduce the output rate.

Hardening of the workpiece: This situation will mainly appear in austenitic structural materials. This stainless steel flange will have a relatively large turning hardening tendency, so correspondingly, when the turning step is carried out, the tool will naturally be subjected to greater force when it encounters the hardening area, and the wear speed will be larger and the working life will be shorter.

It is easy to stick to the knife: when some hard broken steel chips are turned down in contact with the knife, because of the characteristics of light weight of the debris, it will be adhered to the knife and flange, and the brightness of the flange will decrease.

High turning temperature, large turning force: stainless steel flange in the turning, the turning temperature is very high. And because of the high strength of the raw material, it will have a large turning stress. Under the double action of high temperature and strong stress, the thin area near the edge of the tool will be greatly damaged, speeding up the overall wear of the tool.