At this stage, most stainless steel flange manufacturers pay special attention to the scientific research and development of products in the research and development link, often the development of consumer products.

The aesthetic level of buyers of stainless steel flange is getting higher and higher, and the effect of home decoration is getting more and more attention. Stainless steel flange as a key component of home decoration, will be accompanied by buyers for decades.

Especially in the case of severe homogeneity of industrial products, stainless steel flange selection should pay more attention to the shape of the product design.

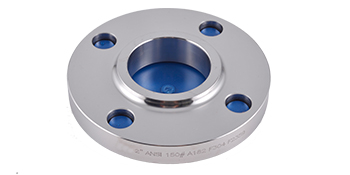

Stainless steel flange pay attention to the shape design

With the rapid progress of the period, the consumer audience gradually younger, 85, 95 become the main consumer, the demand for stainless steel flannel will no longer adhere to anti-theft and wind and rain. The acceptance of high quality training of their pursuit of beauty is more and more high, personalized free and easy, prompting them to stainless steel flange products of higher and higher standards.

Stainless steel flange manufacturers want to choose in this serious market environment, get greater earnings, it is necessary to grasp the market prospects and buyers’ appetite to change the product design, develop in line with the progress of the stainless steel flange products.

The stainless steel flange designed and manufactured by the tooling is composed of two clamping bottom plate, two flange support plates, two vertical plates and four reinforcement plates. In order to ensure the rigidity of the tooling, the welding seam of the connecting plate should be all slotted and welded, and the welding Angle is 20-30 mm high.

Drill a corresponding bolt hole on the support plate of the flange to ensure that the flange can be accurately connected with the support plate of the flange through the bolt. There is a gap between the back of the flange and the support plate for placing small manual jacks.

At the same time, a notch is made on the flange support plate along the vertical plate direction, so that the elbow can be put into the tooling. The tooling of similar groove structure uses thick steel plate, which can meet the rigidity requirements when cutting.

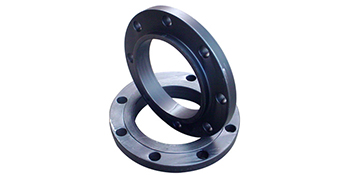

Stainless steel flanges of choice by manufacturer

At present, every major industry will have customized products, which are also favored by buyers. In the case of severe product homogeneity, plagiarism and imitation products continue to appear, and no one can see which product is good.

Stainless steel flange selection manufacturers should also accept custom products, private customization is to create a unique product for the purchaser, the product design has a high standard of stiffness.

Whether it is the change of stainless steel flange shape tone, or sufficient surface treatment technology, should be personalized, should be different from the same industry homogeneous products, this can get a large number of buyers.