Stainless steel flange is a relatively common pipe component, with a very good application range and performance. But many people do not understand the stainless steel flange, so what is the stainless steel flange? What are the advantages? How to maintain daily? I believe you are very curious about these questions, so let’s take a look at it

What is stainless steel flange

Flange, also known as flange, plays a role in connecting the pipe end with the valve in construction. Both sides of the flange are connected with the end of the pipe, and the flange itself has holes. Stainless steel flanges are widely used in petroleum, chemical industry, nuclear power plant, food production, construction, shipbuilding, paper making, medicine and other industries. The reason why stainless steel flanges are used in such a wide range is first because stainless steel flanges have excellent performance.

The original data metal used is stainless steel, and stainless steel itself has very excellent properties. Not simple corrosion, pitting, rust, wear. Stainless steel is one of the high strength materials used in construction metal materials. Stainless steel has good corrosion resistance, so it can maintain the engineering integrity of structural parts for a long time

Stainless steel flange welding process

When welding the stainless steel flange, it is necessary to prevent the flange cover in strict accordance with the requirements to prevent damage. At the time of welding, the current is not too large, and the need to ensure rapid cooling. This is also a good way to operate.

When making stainless steel flanges, what we should use is to add appropriate stability elements to the stainless steel flanges, and such elements can be very stable to a certain extent. Many problems can also occur when welding stainless steel flanges. For example, repeated heating will reduce corrosiveness to some extent. This situation needs attention, otherwise it will seriously affect the quality of the project.

Stainless steel flanges are required to play a connecting role in pipeline engineering, and are generally used in the form of even pairs. The reason why the excellent sealing efficiency can be achieved is largely due to the gasket used for sealing and the bolt used for applying strong pressure.

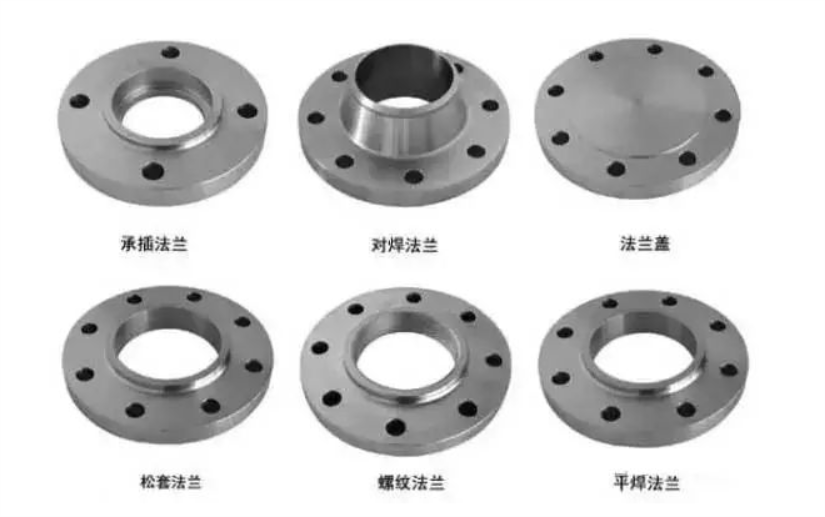

Various types of stainless steel flanges are suitable for different working pipelines – small pressure can be used wire flanges, large pressure to use welding flanges. Flanges under different pressure environments also have corresponding thicknesses and standard models such as gaskets, bolts, pumps and valves