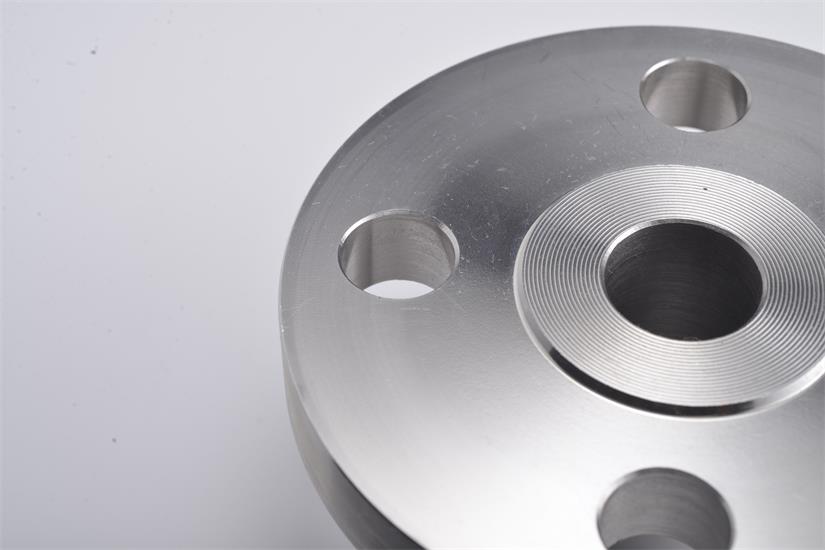

Now the introduction of the flange on the market is still varied, non-professional people for its understanding of the designated professional people, we consulted some professional people, together to see to understand, stainless steel butt welding flange belongs to one of the stainless steel flange, because of its welding form, there is also a common stainless steel flat welded flange.

Stainless steel butt welding flange needs attention

First, the selection of welding process, the current can not be too large, under normal circumstances, it should be less than 20% of the electrode, the arc during the operation should not be too long.

As for rapid cooling between layers, narrow pass technology can also be used, only to prevent the above mentioned situation, stainless steel welded flange can avoid corrosion.

Second, the electrode used must be kept clean, and if necessary, the drying method can be used to promote the drying of the electrode, but here, the stainless steel flange manufacturer reminds you that the drying method can not be recycled to establish a good drying condition and prevent flaking.

Finally, stainless steel butt welding flange manufacturers should remind that after the selection of butt welding method, chromium stainless steel will have a larger hardening specification, and it is easier to crack.

If the same electrode is used for machining, the required preparation steps are preheating and cold treatment to ensure normal operation after the flange is welded.

Stainless steel butt welding flange how to maintain

Stainless steel welded flange must be a product that everyone knows, in fact, it is just a part, use it to connect the two places to each other, such parts are stainless steel flange, very easy to understand. But behind this small part is still very useful, we have to learn how to conserve parts.

The first step, in the case of stainless steel butt welding flange welding, if you want to avoid the corrosion of the cover, in fact, the current can not be too large when welding, so as to quickly cool down, it is also a very good operation method.

Second, when using stainless steel welded flanges, we should most use some appropriate stable elements in the stainless steel welded flanges, such elements can maintain stability to a certain extent.

Of course, some problems will occur when welding stainless steel butt welding flange, for example, if repeated heating will reduce corrosion to a certain extent, if we can pay attention to these things, prevent more, we can maintain well and reduce losses.