The application field of large diameter flange, the scope of use is defined according to different characteristics, and it is mostly used in the case of relatively good material conditions, such as low pressure unpurified compressed air, low pressure circulating water. Its advantage is that the price is relatively good and cost-effective, and the sealing surface of rolled flange can be made into smooth type

Concave and convex type and tenon type three. The application of smooth winding flange is larger, and the other two types of winding flange is also better in use.

Large diameter flange free forging productivity is low, processing allowance is large, but the process is simple and clear, practical, so it is used to forge the shape of simple and clear single piece, small batch production of forgings

Large diameter flange technology

The use of large diameter flange on the basis of the nature of the transport of substances, generally speaking, substances, special substances, toxic substances, flammable and explosive substances; According to the material parameters, working pressure, working environment temperature

In the case that the material is clear, the nominal pressure PN of the flange is clear according to the working environment temperature and working pressure of the material, the connection mode and sealing surface form of the flange and the pipe are clear according to the use place and connection conditions, and the flange specifications are clear according to the connection object.

Technical standard for installation and use of large diameter flanges

The flange produced by the first production should have sufficient strength and cannot be deformed when fastened. The sealing surface of flange should be levelled and clean, and the oil and rust should be carefully removed during installation and use.

Second, the flange wants to match the gasket should have good oil resistance and aging resistance, and better elastic and mechanical strength. Installation and use should be based on the shape of the joint with different section and size of the gasket, and placed accurately.

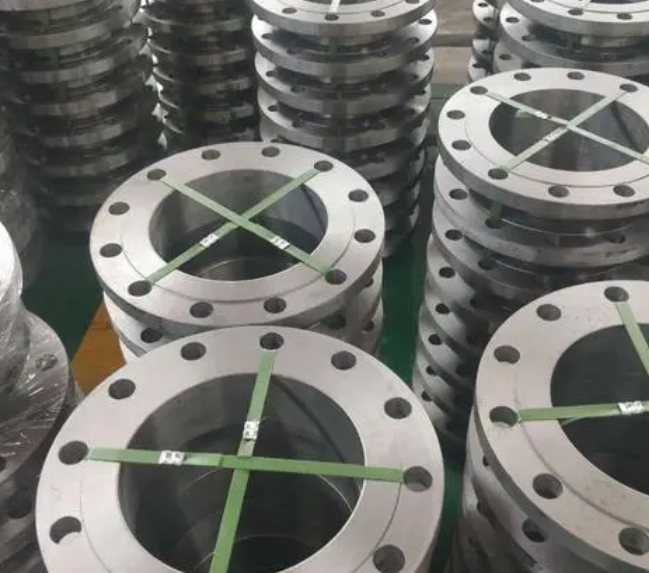

Large diameter flanges are cut into slats with medium plates and then rolled into circles. Rework waterline, bolt hole, etc. This flange is generally large, the larger can reach 7 meters. This kind of flange has better quality guarantee. Because the raw material is medium plate, good density. Material has carbon steel, stainless steel, alloy steel and so on.

Quality of large diameter flange

The use of different processes to produce large flanges have their own advantages and disadvantages, but this is not absolute. For the large diameter flange made of medium plate, the treatment of joint position is the most critical, if this position is not well welded, there will be leakage.

And for the forging of large diameter large flange, there will be a layer of skin after the finished flange comes out, if the bolt hole is just played in the position of the skin, there will be water leakage phenomenon when the pressure.

Therefore, no matter what kind of technology is used to make the flange, it must pass the X-ray detection, only through strict detection to ensure the perfect product.