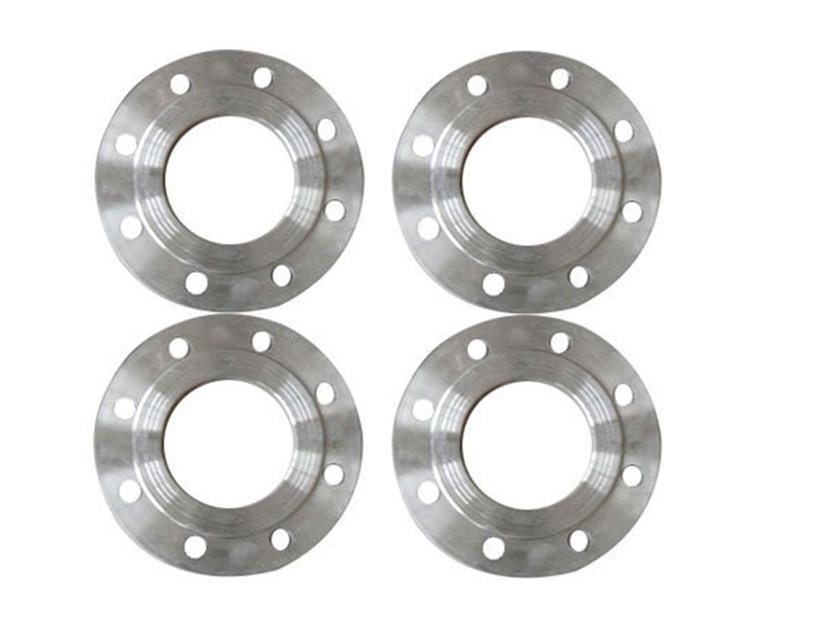

Flanges are a common form of pipe connection used to connect the ends of pipes and equipment or between two pipes. The size of the flange is particularly important for the quality and safety of the pipe connection.

If the flange size is too large, it may cause various problems and consequences, affecting the normal operation of the project. Below we will in-depth analysis of the possible consequences of inappropriate flange size, and introduce solutions to help people better adapt to and avoid the emergence of such problems.

Flange problem answer

Flange connection is not tight resulting in leakage: when the size of the flange is too large, the connection surface can not be fully fitted, resulting in loose flange connections or gaps, and then leakage. Leaks can cause some problems

Leakage will also lead to the loss of materials in the pipeline, wasting valuable resources, and may also cause environmental pollution, especially the impact on groundwater or sensitive ecosystems may be irreversible.

Some media may have hazardous factors, such as chemicals or high temperature media, and leakage can also lead to fire accidents, deflagration or other unexpected events.

Maintenance difficulties: Leaks should be dealt with in a timely manner, but because the leak cannot be easily controlled and treated, it may also need to be shut down and repaired, resulting in decreased production efficiency and increased costs.

The treatment solution is to accurately measure the size of the flange connection before installation to ensure that the size of the flange is in line with the actual needs. For the flange connection with a large size, the gap can be made up by suitable gaskets to ensure that the connection surface is closely fitted.

Use the appropriate force and the correct sequence of bolts to ensure that the flange connection is stable, for the installed flange connection, regular maintenance should pay attention to any signs of leakage, the corresponding repair or replacement.

The solution to frangal breakage

When the size of the flange is too large, the connection surface can not be correctly buttoned, which may cause the flange connection to be unstable and even crack. This may cause the following problems and consequences

The unstable connection of the flange will increase the stress concentration of the pipe, which may cause the pipe to crack under operating conditions, resulting in the leakage of materials and the shutdown of the pipe for maintenance.

When a pipe breaks, it can cause physical damage to workers or those around them, especially for pipes with high pressure, high temperature or dangerous substances.

After pipeline rupture, emergency maintenance must be carried out, resulting in production line suspension, production delays and economic losses. Ruptured pipes can cause damage to the equipment connected to them, requiring repair or replacement of equipment parts, increasing maintenance costs and workload.

Use flange specifications and models that meet engineering requirements to ensure that their dimensions are in line with pipe and equipment connection requirements. In accordance with the accurate installation procedures and technical requirements, the appropriate fastening force is used to ensure that the flange connection is firm and reliable.

Carefully check the quality of the flange connection after installation to ensure that there is no obvious gap or loosening of the connection surface. Regular inspection and maintenance of installed flanged connections are carried out to identify and resolve potential cracking risks in time.