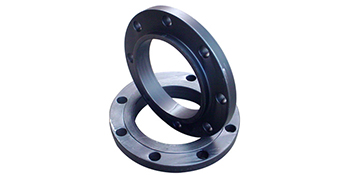

The issue of flat welded flange has been a topic of concern, it is related to the cost or economic benefits of companies and enterprises and many other issues, but the sealing principle of flat welded flange is constantly improving and perfecting.

Lack of flat welded flange

As everyone knows, the main design shortcoming of flat welded flange is that it cannot guarantee no leakage. This is the gap in its design: the connection is dynamic, and at the same time, such as thermal expansion and fluctuating periodic loads will cause movement between the flanges, affecting the role of the flange, resulting in damage to the integrity of the flange, which will lead to leakage.

Any product can not be without defects, but try to control the insufficiency of the product to less, so the company in the production of flat welding flange as far as possible to improve the performance of the product, so that it can play a maximum role.

The size of the tight flange is reduced because the diameter of the seal is reduced, which also reduces the cross section of the sealing surface. Second, the flange gasket has been replaced by a sealing ring to ensure that the sealing face is matched. In this way, very little pressure is required to compact the cover.

With the reduction of the required pressure, the size and number of bolts can be correspondingly reduced, so a new product with small volume and light weight is finally designed.

Therefore, a class of high-quality flange products, such as flat welding flange, alleviates the quality and space, and plays an important role in industrial use.

Sealing principle of flat welding flange

The two sealing surfaces of the bolt extrude the flange gasket from each other to form a seal, but this also causes the damage of the seal. In order to maintain the seal, it is necessary to maintain a large bolt force, so the bolt needs to be made larger.

Larger bolts need to be matched with larger nuts, which means that a larger diameter bolt is needed to create conditions for tightening the nut.

As everyone knows, the larger the diameter of the bolt, the applicable flange will become bent, and the only way is to expand the wall thickness of the flange part. A whole device will require a great size and weight, which becomes a special problem in special circumstances, because weight has always been the main issue that people must pay attention to.

At the same time, the flat welded flange is fundamentally an ineffective seal, which requires 50% of the bolt load to be used for extrusion gaskets, and only 50% of the load for maintaining pressure.