First of all, because carbon steel and water long-term contact will rust, the appearance will change, so we should not put carbon steel flanges in wet and cold areas, in addition, the mechanical properties will also be relatively changed, so we should avoid as much as possible to prevent a lot of inconvenience to everyone.

Then we also need to pay attention to not using hard objects to impact the carbon steel flange itself, so that the appearance of the carbon steel flange will be black and blue, serious if it will destroy the sealing surface, so that the future seal is unstable

The rise of all kinds of new objects in the flange continues, and the development trend in this kind of steel pipe industry also continues to create high kinds of objects to sell steel pipes

In fact, carbon steel flanges are also gradually developing in the scope of steel, so what is the application of carbon steel flanges in construction projects, let’s take a look at it

Application of carbon steel flanges

Large carbon steel flanges should be based on the corresponding conditions and regions and their use characteristics and competitive advantages, for different use areas, play a key role and value in the use and construction. If the use is not good, it is very easy to cause the flange manufactured by the flange manufacturer to crack.

In pipeline engineering, flat welded flanges are mainly used for pipeline access, and high pressure flanges are mostly butt welded flanges. In view of the need for pressure resistance function, they have the characteristics of not easy to change, good sealing characteristics and wide application fields.

The flange has a more complex flared structure, its characteristics are stiffness and elasticity in relative provisions, reasonable welding thinning transition period, welding gaps avoid joint

Buy carbon steel flange points of attention

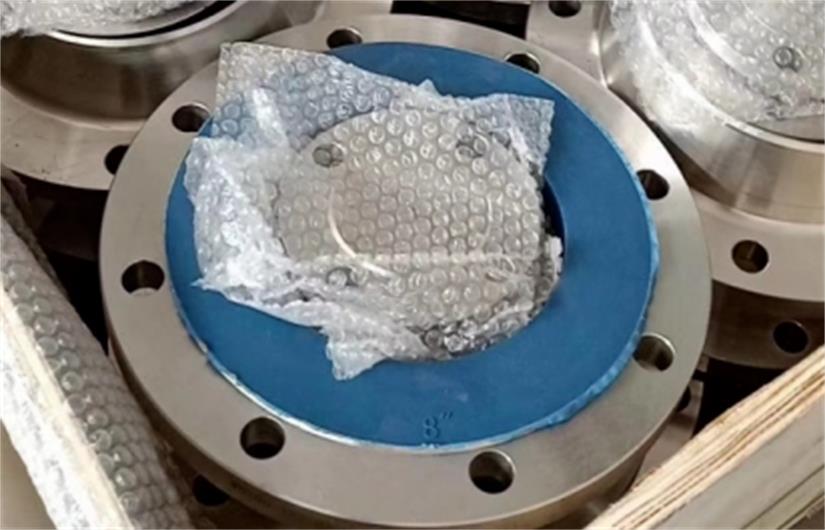

The choice must be made according to the use of the environment, do not put the flange directly on the ground, put some anti-moisture MATS on the ground, and then place the flange neatly.

After placement, there will be a passage between the carbon steel flange and the carbon steel flange, which allows the front end to be ventilated, and it is necessary to promote the expansion of the carbon steel flange.

Different materials should be placed separately and marked, the same materials, different models and specifications should be placed separately, and the corresponding marks should be placed neatly to avoid bumps.

The above is the application of carbon steel flanges in construction projects, it is shared here, want to know more about the knowledge of flanges, you can leave a message below, we will be the first time to answer your questions