When milling stainless steel flanges, milling efficiency and service time are decisive factors in the economic impact of a compromise. There is a kind of mixing equipment company to test its machining process and was able to find a significant improvement in the efficiency of rigid and tough quality stainless steel milling.

With the long service life compared to the competitor’s right Angle face milling cutter, similar to the three parts processed by Ingersoll milling machine under the same cutting conditions, the main processing time is 50%, thus increasing the capacity of additional equipment in 6 hours.

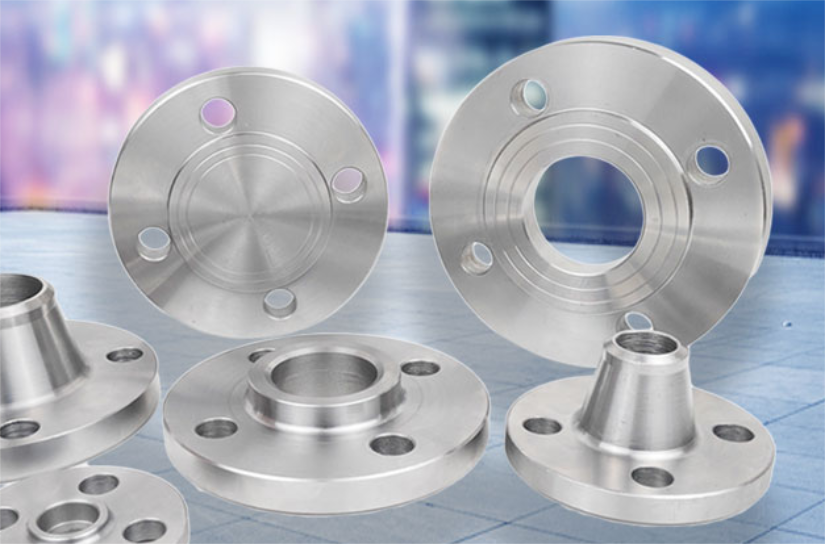

Improve the processing efficiency of stainless steel flanges

During longer runs there will be a free surface of the tumor after the knife and underage wear, so in the future all ladle wet machining. And uses a diameter of 80 mm and has six effective profile milling cutter blades.

In the same numerical cutting, this cutter top flat steel bag 16.7min dry milling, cutting machine with disc competitors, which greatly improves the life of the milling cutter.

Select blanking, after completion, enter the next process, stainless steel workpiece according to the processing requirements into the corresponding process.

Bending should first be based on the size of the drawing, stainless steel material thickness to determine the bending tool and slot, to avoid the product and the tool collision caused by deformation is the key to the selection of the upper die, the selection of the lower die according to the thickness of the plate to determine.

The larger bolt has to match the larger nut, which means that a larger diameter bolt is needed to create conditions for the tightening nut.

As everyone knows, the larger the diameter of the bolt, the applicable stainless steel flange will become curved, the way is to increase the wall thickness of the flange part.

The entire installation will require enormous size and weight, which is a particular problem in offshore environments, where weight is always a major concern.

And, fundamentally, the flange is an ineffective seal that requires 50% of the bolt load to be used to squeeze the gasket, while only 50% of the load is used to maintain the pressure.

Stainless steel flanges do not cause corrosion

Stainless steel is one of the highest strength materials used in building metal materials, because stainless steel has good properties of corrosion flange manufacturers, so it can make permanent structural parts to maintain engineering design, flange chrome stainless steel stamping and at an extended also high mechanical strength

Easy fabrication of components with integrity that can meet the needs of architects and designers of structures, all metals and atmospheric oxygen are reacted to form an oxide film on the surface.