Flanges are used more frequently in pipeline connection projects now, and they can meet the needs of many different pipelines. There are many ways to buy flanges today, but where to buy flanges with high quality and cost-effective? Let’s explore it.

Buying offline is the choice of many people, but due to the expensive rent of offline stores and the expensive labor factors, the overall price of the flanges sold is higher.

For the pursuit of cost-effective consumers, such a way is not very suitable, because the cost of purchase is high, if you need to purchase a large number of flanges, it is recommended to choose online purchase.

There are also many different ways to buy online, mainly including two ways. One is to contact the docking manufacturer directly, and the other is to contact the agent to purchase. Relatively speaking, if it can directly connect with the manufacturer, it is more advantageous. After all, after the lack of intermediate links, you can save a lot of intermediate price difference.

metleader Flange is a professional flange manufacturer, and the flanges produced by the manufacturer are produced in strict accordance with the national standard. It can ensure that the thickness and size specifications of the flange meet the national standard, and the quality of the basic blank used is guaranteed. Being able to buy through such a manufacturer is a good choice, after all, professional manufacturers can provide professional services.

The price of flanges varies greatly

In order to ensure the quality of the flange industry and the industry is not too chaotic, the relevant state departments have certain standards and requirements for the quality of the flange. However, at present, the price of flanges on the market still shows a trend of different levels, which is because the blank material used is different.

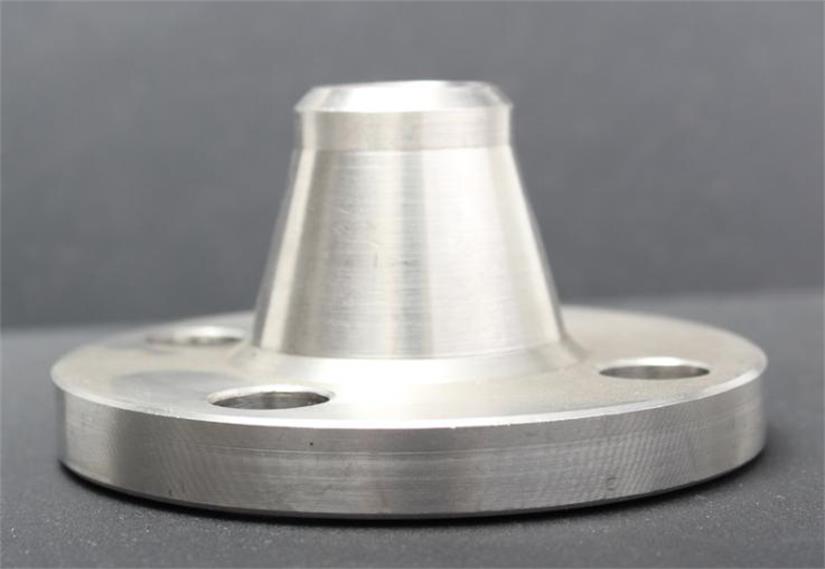

The designer of metleader flange manufacturer indicates that the cost of the material of the flange embryo used is different, and the sales price will be different. Common embryo materials are cast iron, alloy steel, stainless steel, etc., different materials cause differences in manufacturing costs, so the sales price is also different, which is a normal market.

In the process of producing flanges, due to different specifications and different types, there will be a certain gap in the process required. Specifications are an important factor affecting the price, for example, the normal production process of large flanges is more complex, and the blank material used will be more, so the price will be higher than the general flange.

The quotation of flanges produced by different manufacturers is also different, which is because the gap in the experience and strength of the manufacturers has caused the difference in price. Relatively speaking, the overall market sales price of manufacturers with rich experience and professional production lines will be higher than that of general manufacturers.

The price of flange is mainly related to the above reasons. In view of the different production costs, there is no strict unified regulation on the selling price of French in the market, but it must be based on the cost of pricing.