Under the rapid trend of the market economy, all fields have gained equal and better growth. The competition in the market of pipe fittings is also intensifying. As the bottom of the middle and lower reaches of the field of food materials, medicine production, and packaging, the harm of pipe fittings is also increasing. We should pay more attention to it

Because the neck Angle is low, the bending stiffness and bearing capacity of the neck flat welded flange are gradually improved, and the spot assembly is more convenient and popular. It is a more commonly used flange type

So, let’s understand with neck flat welding flange is composed of several parts, with neck flat welding flange basic principle is what. Next, I will give you a brief introduction to the neck flat welding flange, so that you can master it.

Constitution of flat welded flange with neck

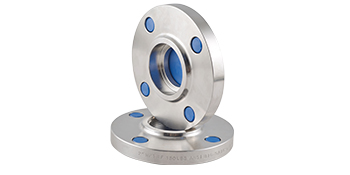

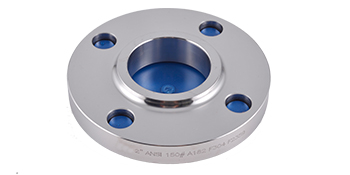

Before understanding the basic principle of a flat welding flange with a neck, we first respond to the previous problem, that is, which parts of a flat welding flange with a neck, in other words, the structure of a flat welding flange with neck, flat welding flange with neck contains flange, flange center has a hole, the flange is also equipped with many screw holes.

One side of the flange is equipped with a neck boss, the inner diameter of the neck convex is the same as the inner diameter of the hole and is connected, and the other side of the flange is equipped with an annular indentation, the center of the annular indentation overlaps with the central axis of the hole, and the radius of the annular indentation is larger than the radius of the hole

An annular indent is also provided within the annular indent, the center of the annular indent overlaps with the central axis of the hole, and the outer surface of the annular indent overlaps with the outer surface of the annular indent.

There are many problems with neck flat welded flange

That is, compared with butt welding flange, flat welding flange with a neck has a large number of welding tasks, high electrode consumption, and can not withstand high temperature and repeated bending and temperature fluctuations.

And relatively speaking, the cost of a flat welded flange is higher. Because of the characteristics of its style, it is easier to get hurt on the road, which is also necessary to pay special attention to the selection of a flat welded flange with the neck.

Do not choose such a buy back, otherwise it is a pile of problems, some problems can not be solved, so buy more carefully, look at a few powerful manufacturers, consult some people familiar with the flange, their own comparison after deciding whether to cooperate with which manufacturer

Well, the above is an introduction to the structure and basic principle of flat welding flange with the neck. I hope you have a deeper understanding of flat welding flange with neck and can use it reasonably in the future