Stainless steel flange is made of stainless steel material, which can meet the performance of withstand strong pressure and tensile. Stainless steel material as one of the highest strength materials in building metal materials, parts processing and use are easy to meet the requirements of architects and structural designers

Metal materials and atmospheric oxygen chemical reaction, the surface will form a layer of oxide film, generally carbon steel formed iron oxide, iron oxide continue to oxidize, the formation of the gap, stainless steel flange has anticorrosion, prevent rust, wear resistance and other advantages, widely used or many

Stainless steel flange welding, flange cover corrosion requirements, when the welding current is small, and ensure that rapid cooling.

Advantage of stainless steel flanges

When making stainless steel flange, we should first use the stainless steel flange to increase the appropriate stability factor, such elements can be fixed to some extent, welding stainless steel flange will also produce a lot of problems.

For example, repeated heating reduces corrosion to some extent. This situation needs attention, otherwise it will seriously affect the quality of the project.

The solution to the stainless steel flange method is to replace parts or replace the flange, can not be solved at the construction site, polymer composite material is suitable for on-site plugging, this is a way

Especially in the flammable and explosive situation, show its advantages, safe and simple, low cost, for the enterprise to solve most flange leakage problems, eliminate safety risks, for the enterprise to save more maintenance costs.

Welding process of stainless steel flange

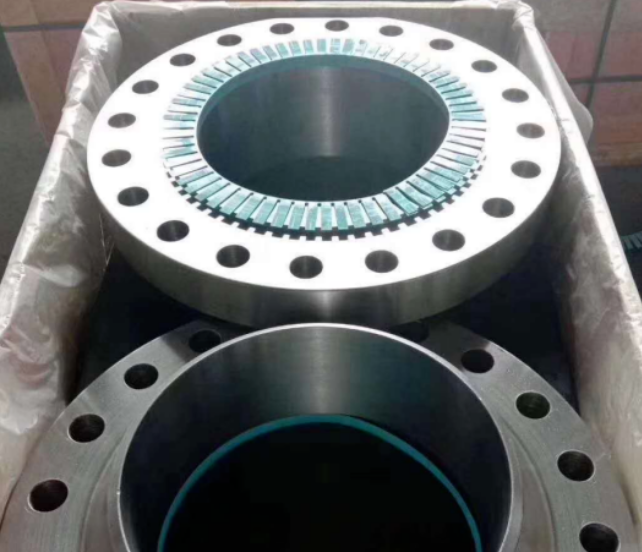

Choose the flange of the supporting gasket, flange plays a very important role in the connection of the pipe, but the gasket is also essential, asbestos is a kind of excellent performance material, it can resist acid, gas and liquid can be absorbed by asbestos, so stainless steel will not be affected. Of course, in some special occasions, will also use other materials made of gaskets, at this time, will choose and stainless steel complementary capacity of the gasket.

Flange production should consider connection, when connecting the pipe, there are different methods, there are thin tubes can be directly connected with threaded flange. Some stainless steel flanges need to face some high pressure pipes, so the need to weld, so more solid and reliable, flange made of stainless steel material, whether it is a high pressure or low pressure pipe, are suitable for welding.

Stainless steel welding connection is very convenient, easy to carry out, the diameter and thickness of stainless steel flange is related to the pipeline pressure to face, in general, the greater the pressure, the thicker the stainless steel flange.