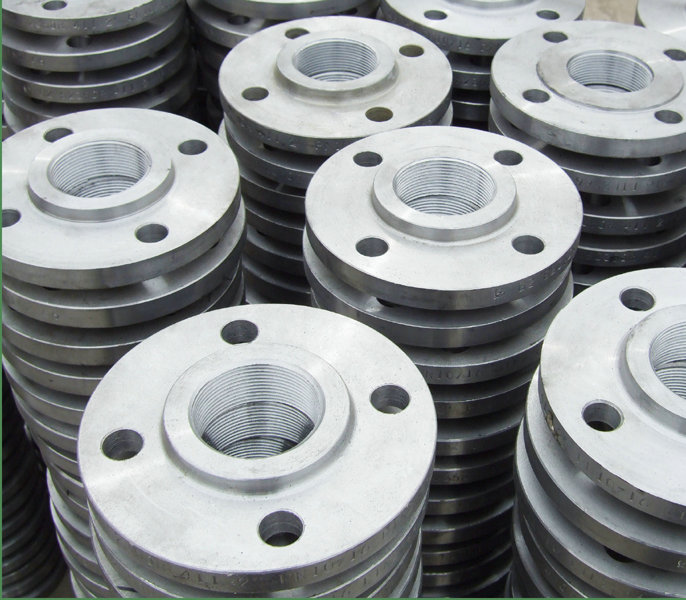

Flat welded flange is a common component in the construction of pipeline engineering, because flat welded flange in the use of links have many advantages, so the use of the area is quite common, and I believe that everyone also have a lot of curiosity for stainless steel flat welded flange, so what are the characteristics of flat welded flange? Let’s discuss it together

Features of stainless steel flat welded flange

Stainless steel flat welded flange in the actual use of links, although there are relative advantages, but its defects are also quite prominent, because of some flaws in their own formulation, so it is difficult to ensure that the flat welded flange in the case of connection without leakage.

The following are some defects in the development of stainless steel flat welding flange: The connection is dynamic, regular load such as thermal expansion and fluctuation will cause the middle operation of the flange surface, harm the function of the flange, and then destroy the integrity of the flange, and then cause leakage.

Any product is unlikely to find defects, only try to avoid the shortage of products in a low degree of manipulation, so in the production process of flat welding flange, as long as continuous improvement, can reasonably improve the characteristics of flat welding flange, as far as possible to avoid reducing leakage, so that flat welding flange plays a larger function in welding.

Stainless steel flat welded flange not only saves area and net weight, and in order to ensure that the connection head can not leak, has a good sealing characteristics. Tight construction results in a reduction in the size of the flange itself and a reduction in the diameter of the seals. Secondly, the flange gasket has been replaced by the sealing ring to ensure that the sealing surface matches.

In this way, the outer cover can be clamped tightly with little pressure. As the pressure required decreases, so does the size and number of bolts. And then develop a small body, light weight new products. Therefore, flat welding flange is a relatively high quality flange product, reduce the quality and area, in the industrial application plays an important function.

Disadvantages of stainless steel flat welded flange

When we use stainless steel flange, not only save space, reduce weight, more important is to ensure that the joint parts will not leak, with good sealing performance. The compact flange size is reduced by reducing the diameter of the seal, which will reduce the cross section of the sealing surface. Secondly, the flange gasket has been replaced by a sealing ring to ensure that the sealing face matches the sealing surface

However, the main design disadvantage of flat welded flanges is that they are not guaranteed to be leak-free. This is the weakness of the design: the connection is dynamic, and periodic loads such as thermal expansion and fluctuations can cause flange faces to move, affecting the function of the flange, thereby compromising the integrity of the flange, and eventually leading to leakage.

No product can be without defects, just try to control the deficiency of the product to a minimum, so the company in the production of flat welding flange as far as possible to improve the performance of the product, so that it can play a maximum role