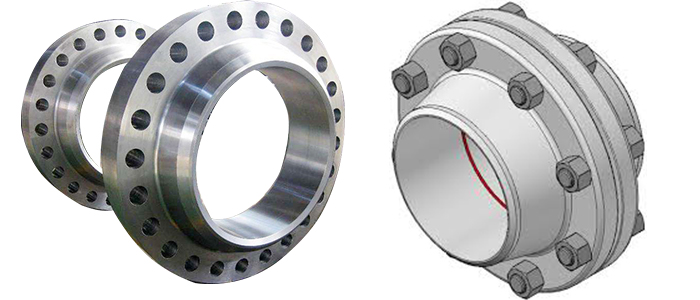

Stainless steel weld neck flange

Stainless steel Weld Neck Flanges square measure flanges that designed to be joined to a piping system by butt fastening. the WN rim is comparatively high-priced owing to its long neck, however is most popular for top stress applications. The neck, or hub, transmits stresses to the pipe, reducing stress concentrations at the bottom of the Welding-Neck flanges. The gradual transition of thickness from the bottom of the hub to the wall thickness at the butt weld provides vital reinforcement of the Weld Neck rim. The bore of the Weld-Neck rim matches the bore of the pipe, reducing turbulence and erosion.

Weld Neck rim manufacturer Landee provides Weld Neck Flanges, WN Flanges, Welding-Neck Fittings in steel, stainless-steel, steel, etc.

WN Flange Proper rust preventing oil painting is done on this WN Flange to make it have exceptional resistance to corrosion. This WN Flange is available in myriad designs and sizes to cater to different applications.

The weld neck flange is a flange type that is usually used with pipes, as opposed to pressure vessels. The design of the flange allows for a full penetration weld at its base where it connects to the pipe. This weld can be X-ray inspected for quality control.

The weld neck flange comes in two types, regular and long. The hub of the weld neck is designed to reduce the stress at the base of the flange. Regular weld neck flanges are used with buttweld fittings and connecting two pieces of pipe together. Long weld neck flanges are usually used with equipment and vessel nozzles. A long weld neck flange is rarely used with pipe.

Both types of flanges are bored to match the inside diameter of the pipe or fitting to which it will be welded to. However, if the bore does not match, the inner diameter can be ground out to match the larger bore pipe. Weld neck flanges are suitable where high pressure, extreme temperatures, shear impact and vibratory stresses apply.